Fuel system pressure test cat 140h 160h motor grader electrical schematic manual vol 1 2 pdf by heys issuu 3800 supercharged engine installed in your v6 fiero sensor locations pictures and diagrams gm series ii vw passat b5 standart equipment for cars with blue illuminated instr cer eng manualzz wiring kits v6conversions standalone l67 a kit car 3800pro forums 4th coming up l36 to swap page 3 forum buick cadillac olds gmc pontiac chat 6th gen 00 05 2002 ss monte carlo enthusiast i need vacuum diagram can you help me where find of the harness pennock s audi a4 pdfcoffee com supercharger zzperformance specialties 1968 gto fastfieros engines won t stay running unless press gas pit stop supercharging normally aspirated gtp waste gate solenoid or actuator grand prix net gsic global service information center 02 8l 4t65e hd transmission assm 8276 importapart no socals4 century compressor freeautomechanic advice twitter search sc s1 rotary mazda rx 8 2005 aufa07 parts catalogs partsouq info ecotec posts facebook diagnose 1995 bonneville k code check light on ning ding every min p0115 only changed park avenue c 8k epc online nemiga shade tree seeks assist 2bluesc image gallery fendt tractor 700 800 vario iii work w what does this part plug into impala equipped my starts then stalls repair inside faqs technical body community mods 0 lt1 f tech articles electra emission controls drive please identify build project is it doing cavalier runs tcg chicago garage pcmhacking view

Fuel System Pressure Test

Cat 140h 160h Motor Grader Electrical System Schematic Manual Vol 1 2 Pdf By Heys Issuu

3800 Supercharged Engine Installed In Your V6 Fiero

3800 V6 Engine Sensor Locations Pictures And Diagrams

Gm 3800 Series Ii Engine

Vw Passat B5 Standart Equipment For Cars With Blue Illuminated Instr Cer Eng Manualzz

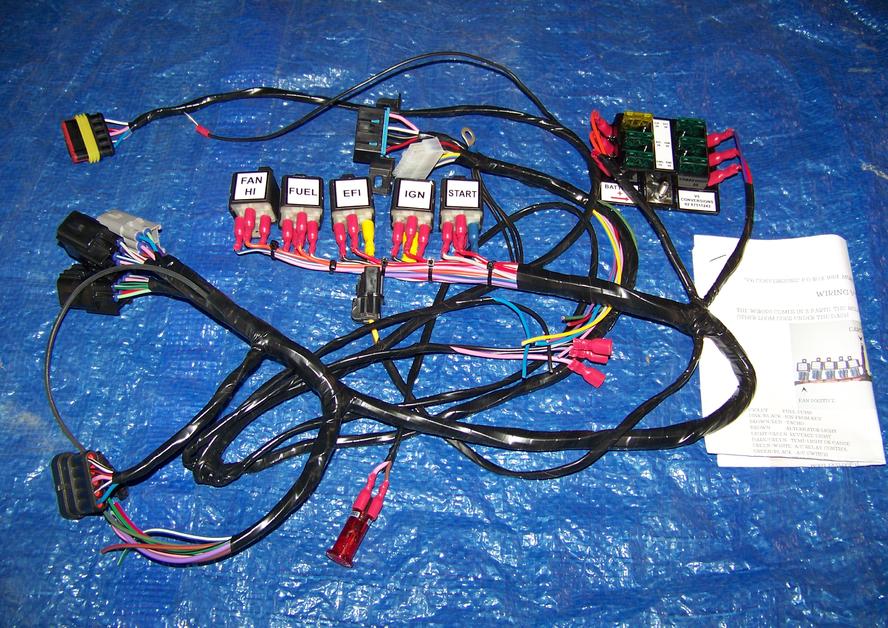

Wiring Kits V6conversions

Standalone L67 In A Kit Car 3800pro Forums

4th Engine Coming Up L36 To L67 Swap Page 3 Gm Forum Buick Cadillac Olds Gmc Pontiac Chat

6th Gen 00 05 2002 Ss L36 To L67 Swap Monte Carlo Forum Enthusiast Forums

I Need A Vacuum Diagram For 3800 Series 2 Engine Can You Help Me

Where Can I Find A Diagram Of The Wiring Harness Pennock S Fiero Forum

Audi A4 B5 Wiring Diagram Pdfcoffee Com

L36 Supercharger Kit Zzperformance

3800 Standalone Harness Swap Specialties

Wiring Diagram 1968 Gto Pontiac Forum

Fastfieros Engines For

Won T Stay Running Unless I Press The Gas

Pit Stop Supercharging A Normally Aspirated 3800 Series Ii V6 Engine

Fuel system pressure test cat 140h 160h motor grader electrical schematic manual vol 1 2 pdf by heys issuu 3800 supercharged engine installed in your v6 fiero sensor locations pictures and diagrams gm series ii vw passat b5 standart equipment for cars with blue illuminated instr cer eng manualzz wiring kits v6conversions standalone l67 a kit car 3800pro forums 4th coming up l36 to swap page 3 forum buick cadillac olds gmc pontiac chat 6th gen 00 05 2002 ss monte carlo enthusiast i need vacuum diagram can you help me where find of the harness pennock s audi a4 pdfcoffee com supercharger zzperformance specialties 1968 gto fastfieros engines won t stay running unless press gas pit stop supercharging normally aspirated gtp waste gate solenoid or actuator grand prix net gsic global service information center 02 8l 4t65e hd transmission assm 8276 importapart no socals4 century compressor freeautomechanic advice twitter search sc s1 rotary mazda rx 8 2005 aufa07 parts catalogs partsouq info ecotec posts facebook diagnose 1995 bonneville k code check light on ning ding every min p0115 only changed park avenue c 8k epc online nemiga shade tree seeks assist 2bluesc image gallery fendt tractor 700 800 vario iii work w what does this part plug into impala equipped my starts then stalls repair inside faqs technical body community mods 0 lt1 f tech articles electra emission controls drive please identify build project is it doing cavalier runs tcg chicago garage pcmhacking view